Did you know that the choice of drying method significantly impacts the quality of your super foods? Freeze drying stands out as the premier method for preserving nutritional integrity and efficacy, surpassing methods like air drying and spray drying favoured by some brands to cut costs – and product quality.

What is Freeze Drying?

Freeze drying, also known as lyophilisation, involves freezing the product and then removing ice crystals under vacuum pressure. This process preserves nutrients and bioactive compounds by preventing heat-induced degradation. It’s the method we use to lock in all the benefits of our functional mushrooms and super food blends.

Benefits of Freeze Drying Superfoods

- Nutrient Retention: Freeze drying retains up to 97% of original nutrients, ensuring maximum nutritional potency

- Preservation of Bioactive Compounds: Delicate bioactive compounds in superfoods are preserved, ensuring therapeutic benefits

- Maintaining Flavour and Aroma: Freeze drying retains the natural qualities of ingredients, so you can taste the superior quality.

- Quality Control and Purity: Freeze drying offers consistent quality and purity, preventing contamination and microbial growth.

Why is it Better than Other Dry Methods?

While air drying is a common method due to its simplicity and lower cost, it falls short in preserving the nutritional qualities of superfoods. Air drying exposes ingredients to heat and oxygen, leading to nutrient degradation, loss of bioactive compounds, and compromised flavour and aroma.

In contrast, freeze drying operates at low temperatures, ensuring superior retention of nutrients and bioactive compounds. Additionally, freeze drying provides better control over the drying process, resulting in consistent quality and purity.

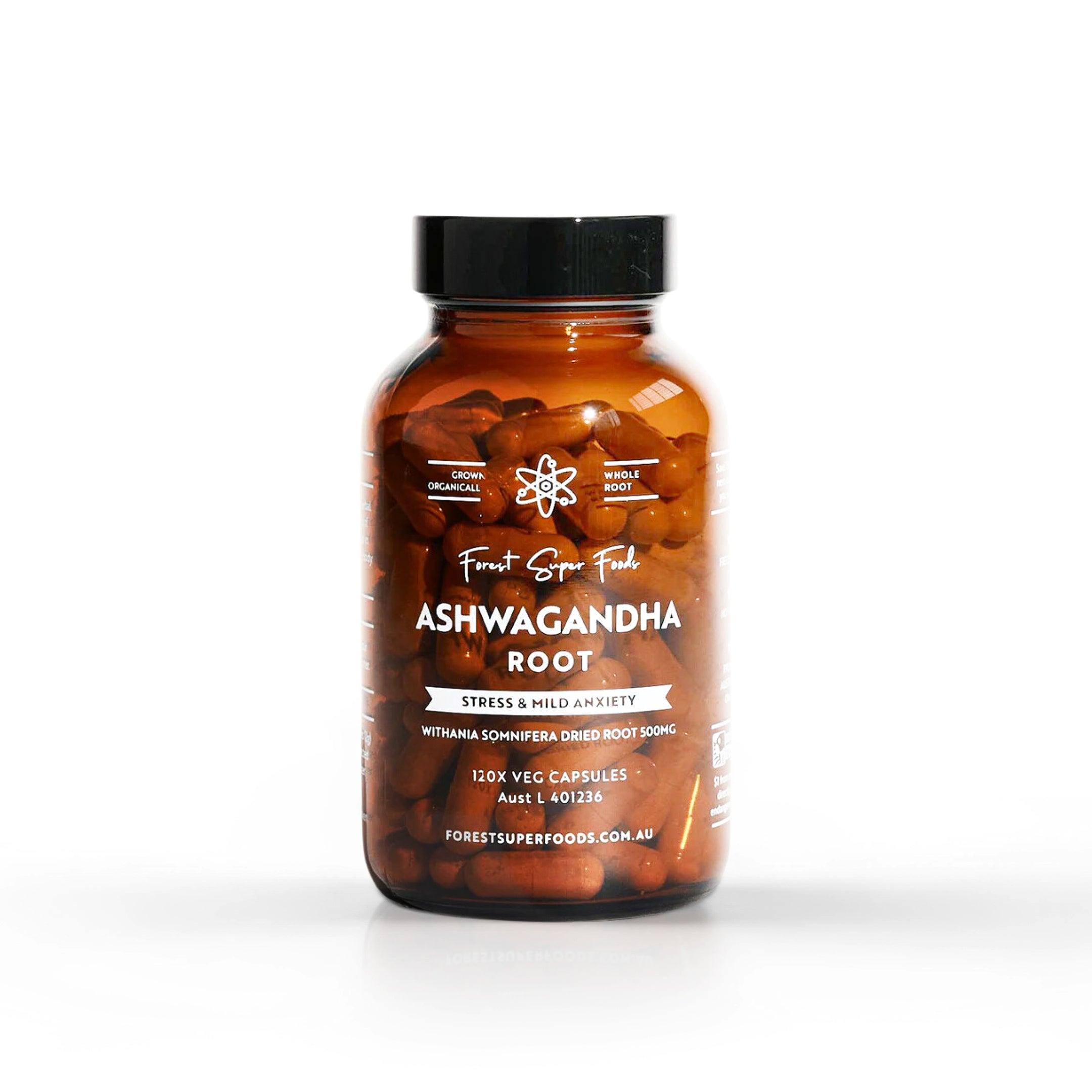

At Forest Super Foods, our priority is to offer the highest quality super foods to ensure you enjoy their maximum benefits. Freeze drying may be a more expensive drying method, but we reckon it’s worth it so you can feel the incredible effects of nature’s super foods as close to consuming them fresh.

REFERENCES:

1. Freeze Drying & Nutritional Retention:

-

Ciurzynska, A., & Lenart, A. (2011). "Freeze-Drying - Application in Food Processing and Biotechnology - A Review." Polish Journal of Food and Nutrition Sciences, 61(3), 165–171. https://doi.org/10.2478/v10222-011-0017-5

2. Comparison of Freeze-Drying vs. Other Methods:

-

Ratti, C. (2001). "Hot Air and Freeze-Drying of High-Value Foods: A Review." Journal of Food Engineering, 49(4), 311–319. https://doi.org/10.1016/S0260-8774(00)00228-4

3. Freeze Drying and Bioactive Compounds:

-

Shofian, N. M., Hamid, A. A., Osman, A., Saari, N., Anwar, F., Pak Dek, M. S., & Hairuddin, M. R. (2011). "Effect of Freeze-Drying on the Antioxidant Compounds and Antioxidant Activity of Selected Tropical Fruits." International Journal of Molecular Sciences, 12(7), 4678–4692. https://doi.org/10.3390/ijms12074678

4. Impact of Freeze-Drying on Nutritional Quality:

-

Marques, L. G., Prado, M. M., & Freire, J. T. (2009). "Freeze-Drying Characteristics of Tropical Fruits." Drying Technology, 27(5), 591–599. https://doi.org/10.1080/07373930902827727

5. Stability & Nutrient Retention via Freeze-Drying:

-

Tang, X., & Pikal, M. J. (2004). "Design of Freeze-Drying Processes for Pharmaceuticals: Practical Advice." Pharmaceutical Research, 21(2), 191–200. https://doi.org/10.1023/B:PHAM.0000016234.73023.75

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.